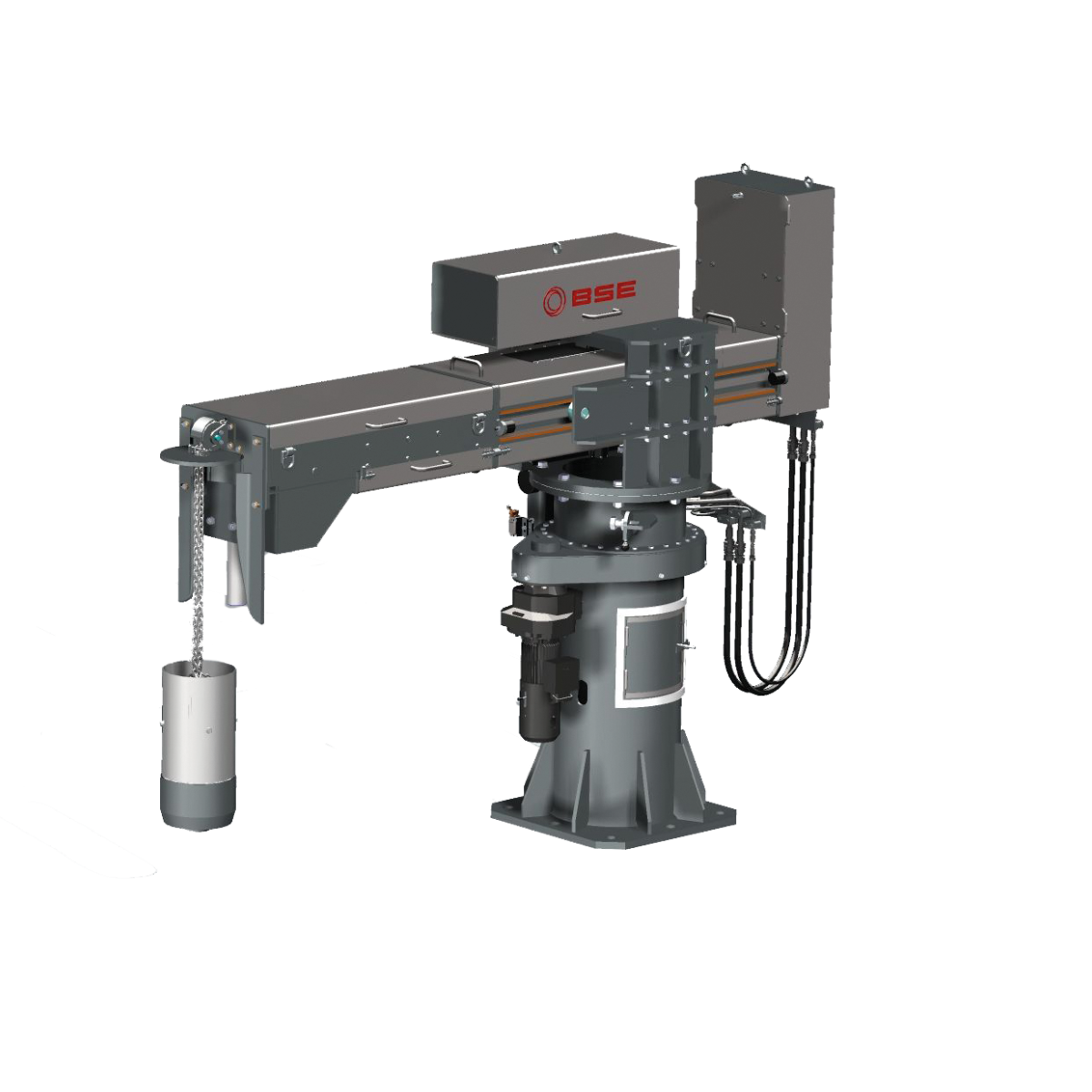

SandMan® for Ladle

Field of use:

SandMan® for Ladle

In continuation of our strategy "The future is manless", the SandMan® for Ladle is another step in this direction

It addresses two fundamental priorities on every ladle of EAF and integrated plants:

- Precise filling of the well block with well filler sand and therefore enabling a better opening rate.

- The filling of the well block is still done manually in most plants today and tracking for a process optimization is not possible without measurements.

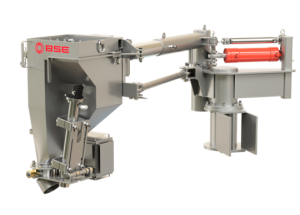

This unique manipulator combines both of these aspects in a robust and space

saving design.

The SandMan® for Ladle pushes safety forward tremendously by removing a dangerous everyday task and keeping operators out of harm's way.

Functions

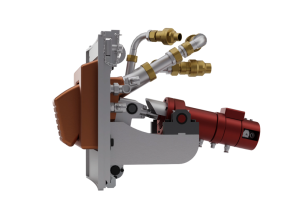

- Automated filling process of well filler sand

- Precise dosing

- Exact placement of sand

- Temperature measurement of ladle bottom

- Visual camera inspection

- Self-standing control cabinet with data recording

Ladle - SandMan @ BSW

Advantages

- Safe Operation from pulpit

- No manual sand dropping -> improved ergonomics

- Less sand consumption

- Improved Opening rates -> no manual lancing -> no loss of sequence -> no downgrading

- Process standardization leads to higher efficiency

- Optimized positioning & tracking

- Tracking and Analysis of potential errors

Experiences

- Installed in January 2021 at BSW

- Well received by operators

- Opening rate has increased from 93.5% to 99.5% so far

- In 24hr Operation since March 2021

- Total cycle time of 60 seconds

- Instead of 20kg, only 15 kg of well filler sand needed (107t ladle)

- Redcution by 25% well filler sand for each ladle