Fluid Dynamic Model

Fluid Dynamic Model

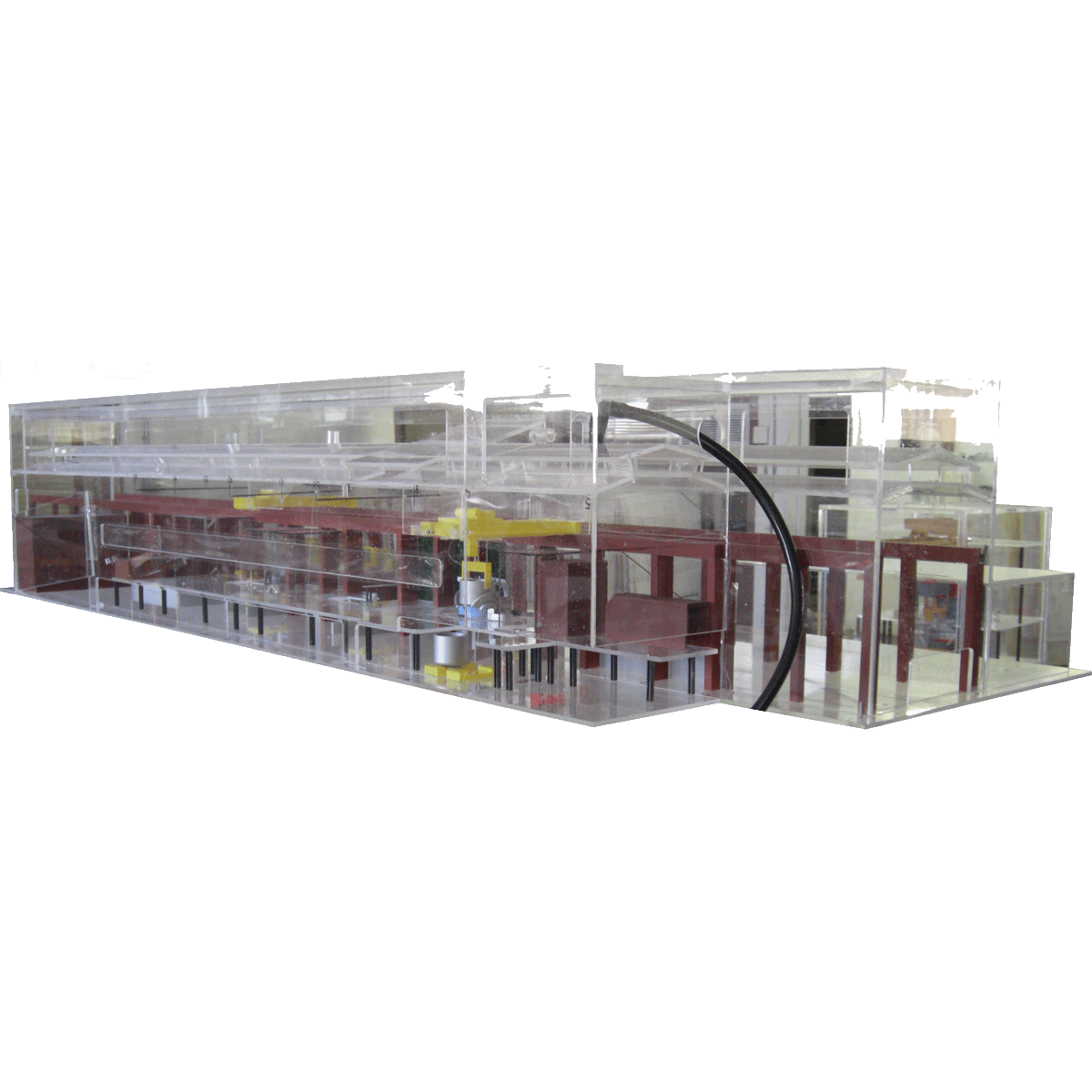

The Fluid Dynamic Model (FDM) study helps to understand and improve the building ventilation and working conditions.

FUNCTIONS

- Analysis tool to understand the building ventilation and to improve the working conditions

- Using a scaled Plexiglas® replica of your melt shop gives an easy, accurate and economical way of simulating the inside shop conditions

- Simulation of heat and dust sources, crane movements as well as wind loads

- Exhaust points can easily be relocated, flow rates adjusted, and building geometry rapidly modified

Fluid Dynamic Model

ADVANTAGES

- Good way to understand melt shop evacuation parameters

- Easy way to determine necessary flow rates

- Partition- and curtain walls can easily be installed or modified

- Canopy hood volume and geometry optimization

- Local dust evacuation and capture

- Plexiglas replica of the FDM can be reused

EXPERIENCES

- Used for all BSW upgrades during the past 40 years

- Execution of more than 70 FDMs

- Customers are 100% satisified with the solutions